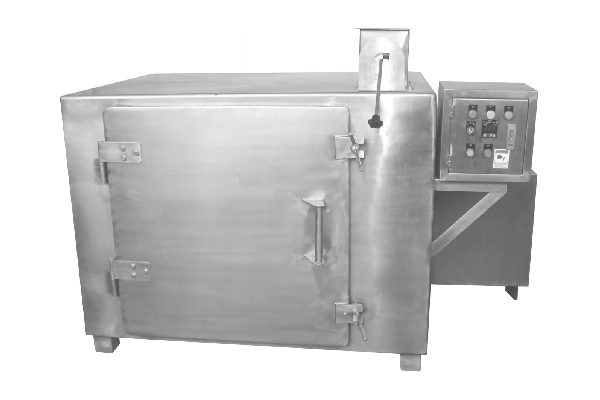

Tray Dryer

KEY FEATURES

- cGMP Compliant Design with 304/316/316L for pharmaceutical applications, or with external mild steel & SS internal contact parts for cost efficiency.

- Flexible Heating Systems - Choice of Electric, Steam, or Thermic Fluid Heating to suit process requirements.

- User-Friendly Control Panel - Equipped with process timer; optional circular chart recorder can be provided at extra cost.

- Sturdy Trolleys with Castor Wheels

- Efficient Air Filtration - Standard air filter at inlet; optional HEPA filter available for enhanced filtration.

- Easy Maintenance & Cleaning

- Exhaust duct, blower, and air inlet filters can be installed outside the production area with suitable ducting, for cleaner working environment.

- Provides uniform airflow across all trays for efficient drying results.

ABOUT TRAY DRYER

Tray Dryer is used for the best drying results in conventional process. It is a double walled cabinet with one two doors. The gap between two walls is filled with high-density fiber glass wool insulation material to avoid heat transfer. Doors are provided with gaskets. Stainless steel trays are placed on the movable trolleys.

Dynamically balanced axial flow type blower fans are provided for uniform air circulation in the drying chamber during process. Machine is provided with control panel board with process timer. Digital temperature controller cum indicator etc.

Capacity

- 6, 12, 24, 48, 96, 192 trays. Standard & GMP models available.

- S.S. 316/316L internals & S.S. 304 externals

- Stainless steel tray in S.S. 316/316L quality.

TECHNICAL DATA

| Model | ATD-12" | ATD-24" | ATD-48" | ATD-96" | ATD-192 |

|---|---|---|---|---|---|

| Tray Size | 16" (Length) x 32" (Width) x 1.25" (Height) in SS 304/316 | ||||

| Motor (in HP) | 0.5 | 1 | 1 | 1 (2 Nos.) | 1 (4 Nos.) |

| No. of Trolley | Nil | Nil / 1 | 1 | 2 | 4 |

| Heating Load (in kW) - 100 deg. C | 3 | 6 | 9 | 18 | 36 |

| Heating Load (in kW) - 200 deg. C | 6 | 9 | 15 | 24 | 42 |

| Heating Load (in kW) - 300 deg. C | 9 | 12 | 21 | 30 | 48 |

| Steam Consumption | 25 Lbs / hour | 45 Lbs / hour | 60 Lbs / hour | 80 Lbs / hour | 120 Lbs / hour |